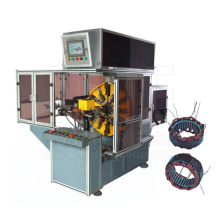

Automatic Statorwinding and Inserting Machine

Basic Info

Model No.: RQ01-100

Product Description

Model NO.: RQ01-100

Wire Diameter: 0.31-1.2 Mm

Machine Dimension: (L)2000*(W)1100*(H)2200

Air Pressure: 0.6~0.8MPa

Temperature: :0~40oc

Origin: China

Stator Stack Length: 30-140 Mm

Machine Weight: 4500kg

Power Source: 380V±10%, Three Phase Four Wires

Power: 20kw

Trademark: NIDE

Introduction:

This machine is designed for electric motor stator winding and inserting, 4 working stations complete the winding, making wedge and inserting, it has 2pcs winding stations, 1pc wedge making station and 1pc inserting station.

Winding station: the winding tooling is fixed by eccentric structure and inserting tooling, it's helpful for reducing the vibration during winding process. The windings/coils are put into the inserting tooling automatically. At the winding unit, it completes automatic jump, automatic hook and cut wire, automatic indexing. The winding tension is adjustable, the winding unit has enamel scratch detection alarm function.

The wedge making station: servo feeding, servo cutting, it regularly clean the wedge chips automatically, it's helpful for avoid wedge stuck, and helpful for machine stable running.

The inserting station: servo inserting, the winding/coil pushing height and wedge pushing height is set on the touch screen.

This four stations are driven by cam clearance divider, they work simultaneously and no interference to each other. It's labor-cost saving and high efficiency.

Technical Specification:

Stator stack length: 30-140 mm

Wire diameter: Φ0.31-1.2 mm(enamel layer is not included)

Adapts AC servo motor system as the power source for winding, module dipping, cup dividing, wire hooking and cutting, wedge feeding and cutting, and adapts three phase frequency converter reducer as the power source for turntable indexing.

Adapts servo motor control the main spindle, it can set acceleration and deceleration time, the turn No. accuracy is ±1 turn.

Winding head: 1~3pcs, max. 3pcs wire parallel winding.

No obvious vibration or noise.

Winding is tidy, no damage or peel-off for the enamel, the machine will stop once the copper wire is finished.

Wire Hooking and cutting XY axis front-back Left-right motion are servo motion system controlled, the across wire and lead wire length is adjustable.

Module dipping is controlled by servo system, Max.4 section.

Flyer swing diameter: 300mm

Max. 20sets winding data can be saved on the touch screen

The inserting tooling exchanges between the four stations adapt cam indexing unit, adapts frequency converter to control the speed.

The rotation motion of the Winding flyer is driven by 2pcs 3KW servo motor.

The up-down of the winding tooling is driven by 2pcs 1kw servo motor.

The left-right front-back of the wire hooking arm is driven by 4pcs 0.75kw servo motor.

The wedge is feeding by servo motor, the wedge inserting slot can be set. The wedge can be cut in set length.

Production cycle time: 40sec/pc(auxiliary working time is not included).

Material of the critical parts of the tooling: SKD61(Korea) tooling steel.

The tooling is changeable.

The winding unit, wedge feeding unit, coil pushing unit and inserting unit has speed pre-reducing function.

The winding speed, module dipping speed, wire hooking arm moving speed, wedge making speed, turntable indexing speed, inserting pushing-up speed and stop time can be set on the touch screen.

No damage, moving or incline problem for the wedge, the wire can't come out of the insulation paper.

Machine weight: 4500Kg

Machine dimension:(L)2000*(W)1100*(H)2200

Power source: 380V±10%, three phase four wires

Air pressure: 0.6~0.8MPa

Power: 20Kw

Temperature: 0~40ºC

Main configuration:

Main controller: Taiwan Yitu CNC motion system

Servo motor and driver: Schneider

Sensor: Omron, Autonics

Motion control switch: Schneider

Relay: Japan IDEC

Touch screen: Kunlun Tongtai

Pneumatic parts: Airtac

Frequency converter: Schneider

Other parts: Tend, Delixi, Schneider

Use grating as the protection device, standing operation.

Accessories:

3pcs inserting blade, 3pcs wedge depot blade, 3pcs pusher, 2pcs winding rod

Contact us if you need more details on Winding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Winding Inserting Machine、Coil Winding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Stator Winding Line > Coil Winding Machine

Premium Related Products

Other Products

Hot Products

LED Light LED Bulb Manufacturing Machines Production LineMotor Shaft Automatic Feeding Machine Shaft Production MachineAutomatic Armature Turning MachineGenerator Motor Stator Insulation Paper Insertion MachineFull Automatic Magnetic Field Coil Winding Shaping MachineStator Varnish Dipping Machine for Stator Insulation TreatmentAutomatic Generator Armature Motor Rotor Balancing Machine with Five StationsArmature Insulation Paper Inserting Machine for DC Motor, Wiper MotorAutomatic Armature Commutator Hook Hot-Stacking MachineHigh Effeciency Fully Automatic Four Working Stations Stator Coil Lacing MachineAutomatic Induction Motor Stator Coil Winding Insertion MachineAutomatic Rotor Coil Winder MachineryEight Working Station Coil Winding MachineBLDC Stator Needle Winding MachineAutomatic Motor Armature Production Machine Assembly LineMotor Stator Automatic Production Assembly Machine (line)