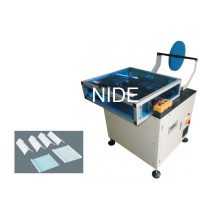

Stator Inslot Wedge Shaping and Cutting Machine

Basic Info

Model No.: CG1-100

Product Description

Model NO.: CG1-100 Automation: Automatic Customized: Customized Paper Feeding Length: 10~200mm Paper Cutting Speed: 120PCS/Min Weight: 150kg After-Sales Service: Overseas Service Center Available Trademark: NIDE Origin: China Paper Thickness: Thin Paper Certification: CCC Condition: New Paper Cutting Thickness: 0.2-0.5mm Power Supply: 220V 50/60Hz Dimension: 450*650*1100mm Machine Color: Ral9010 or as Per Customer Requirement Specification: ISO Working principle

Machine adopts full mechanical action, parameter is controlled by PLC. Feeding by stepping motor, and drives forming structure, to finish wedge forming and feeding; then drive cutting structure to cut wedge by cutting stepping motor.

Technical parameter

Main features

Auto feeding, forming and cutting, small noise, high speed, smooth cutting without burr; feeding length, feeding speed, output can be set in text displayer. This machine is suitable for small and medium three phase motor, gasoline generator motor etc stator wedge forming and cutting.

Machine structure

Common malfunction and solution

Maintenance

1. Before running machine, check mechanical and electrical part, screws are loose or not.

2. After finishing one shift, remove the sundries and clean the machine, and reset the machine.

Competitive advantages

Variety of application, easy operation.

We have Overseas Service Center.

Machine is controlled by PLC. All the parameter can be set in the touch screen.

It is suitable for stators with different model number and dimension.

The operation and tooling change process is easy.

We could customize machine for our customer as per their requirement.

We directly supply our machines to many countries, like USA, France, Turkey, Iran, India, Brazil, Argentina, Mexico etc.

Contact us if you need more details on Cutting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Forming Machine、Wedge Shaping and Cutting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Machine adopts full mechanical action, parameter is controlled by PLC. Feeding by stepping motor, and drives forming structure, to finish wedge forming and feeding; then drive cutting structure to cut wedge by cutting stepping motor.

Technical parameter

| No. | Item | Unit | Parameter |

| 1 | Feeding length | mm | 10~300 |

| 2 | Wedge width | mm | ≤16 |

| 3 | Material thickness | mm | ≤0.35 |

| 4 | Temperature range | ºC | 15~150 |

| 5 | Power supply | 220V/50Hz/60Hz | |

| 6 | Weight | kg | ≈150kg |

| 7 | Dimension | mm | 450×650×1100 |

Main features

Auto feeding, forming and cutting, small noise, high speed, smooth cutting without burr; feeding length, feeding speed, output can be set in text displayer. This machine is suitable for small and medium three phase motor, gasoline generator motor etc stator wedge forming and cutting.

Machine structure

Common malfunction and solution

| Malfunction | Reason | Solution |

| Machine doesn't running after pressing "Start" button | a) Power is OFF; b) Under Emergency stop; c) No paper; | a) Switch ON power b) Loosen Emergency stop button c) Load paper |

| No wedge come out | a) There is sundries at paper exit b) Upper and lower wheel didn't match well | a) Remove sundries b)Adjust gap between upper and lower wheel |

Maintenance

1. Before running machine, check mechanical and electrical part, screws are loose or not.

2. After finishing one shift, remove the sundries and clean the machine, and reset the machine.

Competitive advantages

Variety of application, easy operation.

We have Overseas Service Center.

Machine is controlled by PLC. All the parameter can be set in the touch screen.

It is suitable for stators with different model number and dimension.

The operation and tooling change process is easy.

We could customize machine for our customer as per their requirement.

We directly supply our machines to many countries, like USA, France, Turkey, Iran, India, Brazil, Argentina, Mexico etc.

Contact us if you need more details on Cutting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Forming Machine、Wedge Shaping and Cutting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Stator Winding Line > Others Stator Winding Line

Other Products

Hot Products

LED Light LED Bulb Manufacturing Machines Production LineMotor Shaft Automatic Feeding Machine Shaft Production MachineAutomatic Armature Turning MachineGenerator Motor Stator Insulation Paper Insertion MachineFull Automatic Magnetic Field Coil Winding Shaping MachineStator Varnish Dipping Machine for Stator Insulation TreatmentAutomatic Generator Armature Motor Rotor Balancing Machine with Five StationsArmature Insulation Paper Inserting Machine for DC Motor, Wiper MotorAutomatic Armature Commutator Hook Hot-Stacking MachineHigh Effeciency Fully Automatic Four Working Stations Stator Coil Lacing MachineAutomatic Induction Motor Stator Coil Winding Insertion MachineAutomatic Rotor Coil Winder MachineryEight Working Station Coil Winding MachineBLDC Stator Needle Winding MachineAutomatic Motor Armature Production Machine Assembly LineMotor Stator Automatic Production Assembly Machine (line)