Graphite Rods Welding Electrode Cylinder Rod Bars

Basic Info

Model No.: LB-RP225

Product Description

| Product Description | |

| Graphite Electrode Category | RP---regular powder electrode |

| HP---high-power electrode | |

| UHP---ultra-high-power electrode | |

| Length | 1800-2700mm |

| Diameter | 200-800mm |

| Property | 1. Low resistivity |

Guide to Graphite Electrodes

RP Graphite Electrode Series: RP200, RP250,RP300,RP350,RP400,RP450,RP500,RP550,RP600,RP700

HP Graphite Electrode Series: HP200, HP250, HP300, HP350,HP400,HP450,HP500,HP550,HP600,HP700

UHP Graphite Electrode Series:UHP250,UHP300,UHP350,UHP400,UHP450,UHP500,UHP550,UHP600,UHP700

| Our factory`s special manufacturing technique | |

| Calcining | The annual capacity of the calcining furnace is 160000mts |

|

Dosing, kneading and forming | The high automatic dosing systems comprise kneaders with 2000-4000 liters, the oil extruder of 40MN,35MN and 25MN, large scale vibrating forming machines, 1 set of the 60MN isostatic machine and cold & hot mould machines |

|

Baking and impregnation | Baking and impregnation equipment comprise ring baking furnaces with 30-36 rooms, electrode cleaning machine imported from Japan, tunnel kilns imported from Japan, impregnation system imported from Germany and domestic made impregnation systems |

| Graphitization | Graphitization equipment comprise DC graphitization furnaces and LWG furnaces |

| Machining | Machining equipment comprise one auto-machining line imported from USA. One domestic-made machining line and one pre-assembling iron platform |

|

Pre-formance testing | We have a complete inspection system for testing and analyzing physical and chemical data of carbon material. Our inspection center, the former [quality supervise and inspection center of the metallurgy ministry", is responsible for quality supervision, sampling, inspection and testing for domestic carbon companies. |

Properties of the graphite electrode

| Properties | UHP | HP | RP | ||

|

| Φ300-φ500 | Φ550-φ800 | Φ300-φ800 | Φ300-φ800 | |

| Resistivity (uΩm max) | Electrode | 4.8-5.8 | 4.6-5.8 | 5.8-6.6 | 7.0-10.0 |

| Nipple | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | 4.0-4.5 | |

|

Modulus of rupture (Mpa) | Electrode | 10.0-14.0 | 10.0-14.0 | 10.0-13.0 | 8.0-10.0 |

| Nipple | 20.0-24.0 | 22.0-26.0 | 20.0-23.0 | 19.0-22.0 | |

| Young's modulus(Gpa) | Electrode | 9.0-13.0 | 10.0-14.0 | 8.0-12.0 | 7.0-9.3 |

| Nipple | 15.0-18.0 | 16.0-19.0 | 14.0-16.0 | 12.0-14.0 | |

| Bulk Density (g/cm³)min | Electrode | 1.68-1.74 | 1.70-1.74 | 1.64-1.68 | 1.53-1.56 |

| Nipple | 1.78-1.82 | 1.80-1.84 | 1.75-1.80 | 1.70-1.74 | |

| CTE (100-600℃)max | Electrode | 1.1-1.4 | 1.1-1.4 | 1.6-1.9 | 2.2-2.6 |

| Nipple | 0.9-1.2 | 0.9-1.2 | 1.1-1.4 | 2.0-2.5 | |

| Ash (%) | | 0.3 | 0.5 | ||

Current load and current density

| Diameter(mm) | RP | HP | UHP | |||

|

| Current load(A) | Current density(A/cm3) | Current load(A) | Current density(A/cm3) | Current load(A) | Current density(A/cm3) |

| 200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 |

|

|

| 225 | 6100-8600 | 15-21 | 6500-10000 | 18-25 |

|

|

| 250 | 7000-10000 | 14-20 | 8000-13000 | 18-25 | 8100-12200 | 20-30 |

| 300 | 10000-13000 | 14-18 | 13000-17400 | 17-24 | 15000-22000 | 20-30 |

| 350 | 13500-18000 | 14-18 | 17400-24000 | 17-24 | 20000-30000 | 20-30 |

| 400 | 18000-23500 | 14-18 | 21000-31000 | 16-24 | 25000-40000 | 19-30 |

| 450 | 22000-27000 | 13-17 | 25000-40000 | 15-24 | 32000-45000 | 19-27 |

| 500 | 25000-32000 | 13-16 | 30000-48000 | 15-24 | 38000-55000 | 18-27 |

| 550 | 32000-40000 | 13-16 | 37000-57000 | 15-23 | 42000-66000 | 17-26 |

| 600 | 38000-47000 | 13-16 | 44000-67000 | 15-23 | 49000-76000 | 17-26 |

Nipple Size and Nipple Range (4 buckles)

| Nominal diameter(mm) | Nipple type | Nipple socket average diameter(mm) | Nipple max diameter(mm) | Nipple length(mm) | Nipple socket depth(mm) | Buckle length(mm) |

|

|

| D4 | D1 | L1 | L2 | L3 |

| 800 | 432T4L | 428.64 | 431.80 | 635.00 | 323.50 | 319.50 |

| 750 | 406T4L | 403.24 | 406.40 | 609.60 | 310.80 | 306.80 |

| 750 | 406T4N | 403.24 | 406.40 | 584.20 | 298.10 | 294.10 |

| 700 | 374T4L | 371.49 | 374.65 | 558.80 | 285.40 | 281.10 |

| 700 | 374T4N | 371.49 | 374.65 | 457.20 | 234.60 | 230.60 |

| 650 | 355T4L | 352.44 | 355.60 | 558.80 | 285.40 | 281.40 |

| 650 | 355T4N | 352.44 | 355.60 | 457.20 | 234.60 | 230.60 |

| 600 | 317T4L | 314.34 | 317.50 | 457.20 | 234.60 | 230.60 |

| 600 | 317T4N | 314.34 | 317.50 | 355.60 | 183.80 | 179.80 |

| 550 | 298T4L | 295.29 | 298.45 | 457.20 | 234.60 | 230.60 |

| 550 | 298T4N | 295.29 | 298.45 | 355.60 | 183.80 | 179.80 |

| 500 | 269T4L | 266.72 | 269.88 | 457.20 | 234.60 | 230.60 |

| 500 | 269T4N | 266.72 | 269.88 | 355.60 | 183.80 | 179.80 |

| 450 | 241T4L | 238.14 | 241.30 | 355.60 | 183.80 | 179.80 |

| 450 | 241T4N | 238.14 | 241.30 | 304.80 | 158.40 | 154.40 |

| 400 | 222T4L | 219.09 | 222.25 | 355.60 | 183.80 | 179.80 |

| 400 | 222T4N | 219.09 | 222.25 | 304.80 | 158.40 | 154.40 |

| 350 | 203T4L | 200 04 | 203.20 | 304.80 | 158.40 | 154.40 |

| 350 | 203T4N | 200.04 | 203.20 | 254.00 | 133.00 | 129.00 |

| 300 | 177T4N | 174.64 | 177.80 | 215.90 | 114.00 | 110.00 |

Nipple Size and Nipple Range (3 buckles)

| Nominal diameter(mm) | Nipple type | Nipple socket average diameter(mm) | Nipple max diameter(mm) | Nipple length(mm) | Nipple socket depth(mm) | Buckle length(mm) |

|

|

| D4 | D1 | L1 | L2 | L3 |

| 550 | 298T3L | 294.24 | 298.45 | 457.2 | 234.6 | 230.6 |

| 500 | 273T3L | 268.84 | 273.05 | 457.2 | 234.6 | 230.6 |

| 500 | 273T3N | 268.84 | 273.05 | 355.6 | 183.8 | 179.8 |

| 400/450 | 241T3L | 237.09 | 241.3 | 355.6 | 183.8 | 179.8 |

| 400/450 | 241T3N | 237.09 | 241.3 | 338.7 | 175.30 | 171.8 |

| 350/400 | 215T3L | 211.69 | 215.9 | 355.6 | 183.3 | 179.8 |

| 350/400 | 215T3N | 211.69 | 215.9 | 304.8 | 158.4 | 154.4 |

| 300 | 177T3L | 172.95 | 177.16 | 270.9 | 141.50 | 137.50 |

Guidance of using

| 1. | Use special hoist tools to hoist graphite electrode. It is strictly forbidden to prize electrode ends up with crowbar. It must be handled with great care during transportation to avoid damage. |

| 2. | Graphite electrode must be kept away from being moistened or wetted by rain, snow and water, and must be kept dry. It must be dried in the furnace before use. The drying temperature in the furnace shall be less than 100℃. The drying period shall be not less than 48 hours.

|

| 3. | Not to be stored up near clay, slag etc. To avoid surface pollution and increasing resistivity. |

| 4. | Carefully checking before connection, make sure that the socked and nipple thread is not damaged, nipple pitch plug is in. Nipple screw shall not be damaged during lifting. |

| 5. | Blow the nipple and socket threads with compressed air. |

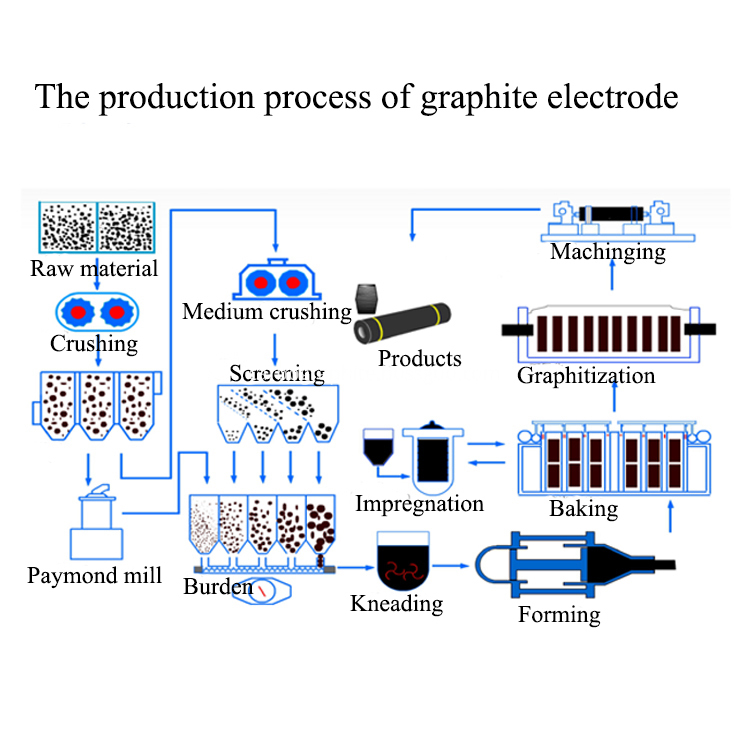

The production process

Packing

Our company can provide third-part test reports before delivery

Customers show

FAQ

| Q: Do you provide samples? | A: Yes, 1-2MT sample order are available for your side to check our quality.Sample order delivery time will be 5-7 days.

For such small order could choose shipping by air or express. |

| Q:Delivery time? | A: Generally, we have goods in stock. The quantity less than 100MT, delivery time is about 10-15days. If more than 100MT, the delivery time will about 20-30days. Exactly time we could confirm depend on order condition. |

| Q: What is your trade terms and payment method? | A: Trade term accept FOB, CFR, CIF, EXW, etc. Payment method usually by T/T, L/C,Western union,Paypal etc. Also can choose other way, we could discuss. |

| Q: How can i get the price early? | A: If you could provide the quantity, grade, size and such specification,we could quote you less than 12hours once see your inquiry ,If you do not know this information, we need contact and confirm then quote to you. |

| Notice | Please note that the price on website is a rough range price. The actual price will depends on raw materials,exchange rate, market,and the order size, grade, quantity and so on.

If you do need the goods, contact us freely. Glad to cooperation with you,Thanks ! |

| Company Information |

| Carbo Graphite group is a manufacturer and trading combo, Since 1992s. Special in the carbon and graphite products. We mainly do the domestic market in the past time. The company begin to exploit the oversea market since 2014. The main products is EP(electrode paste),GE(graphite electrode), CPC(calcined petroleum coke), and also do business for other carbon and graphite items. Our carbon and graphite items have passed the testing specific carbon testing according to JB/T6773-2011.We're sure that the material is in strictly accordance to REACH regulation for EU market. RP 150*1800mm HP graphite electrode for steel making EAF LF Annual output:

|

Contact information

Product Categories : RP Graphite Electrode > RP 225 Graphite Electrode